Have you ever wondered what programmable logic controls mean? We will try to answer this question in the next few lines. A programmable logic controller, or simply a PLC is a solid state-of-the-art computer that monitors inputs and outputs and makes an automated process or automated logic decisions.

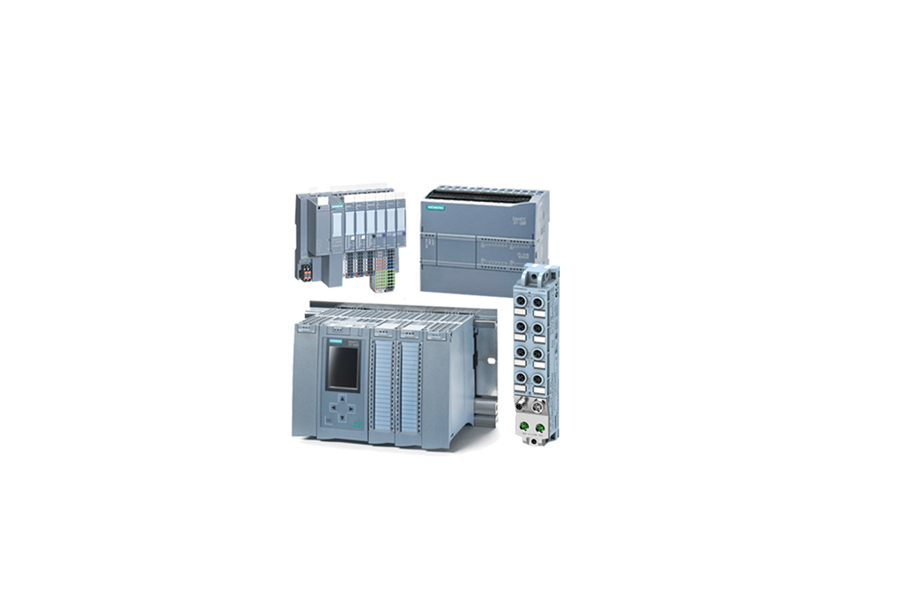

The programmable logic controllers, named in the current jargon PLC, are robust and compact devices specifically designed for monitoring and controlling some process parameters. With their help, various automation schemes of medium complexity can be implemented. Initially, they were designed to implement binary control functions: Combined logic and programmable logic functions (sequential control). Subsequently, additional continuous and adaptive control functions were added, communication functions, and viewing and storage functions of collected data. Today, with their robust, reliable and autonomous character, they are the most used intelligent automation components.

From a constructive point of view, a PLC device consists of:

– Computing microsystem, usually implemented with a microcontroller

– Set of digital and analog interfaces, containing adaptive circuits for industrial signals

– Power supply mode

– Optional: Serial communication interfaces (e.g.: RS232, RS485) and network (e.g. CAN, Profibus)

– Protective case

For application development, different programming environments, such as ISAGRAPH or DX-Developer, can be used to edit, compile, download on a PLC, and execute the program (in normal and step-by-step mode).

For PLCs in the Mitsubishi FX3u family, use the Dx-Developer programming environment that provides 2 programming languages: LD and SFC (command-based). In the present paper, LD is used.

PLCs also have drawbacks. They fail to function properly when dealing with more complex data. See more here. Simple design elements include electromagnets, solenoid valves, servomotors, DC or step-wise electric motors, buzzer and audible warning devices (LEDs or light bulbs), etc. These items require a power supply and a certain drive scheme.

Within the program lines, different types of “devices” are included in the PLC structure, as follows:

– X – Physical inputs (e.g. X000-X007 to the PLC used) – Contact type digital inputs

– Y – Physical outputs (e.g. Y000-Y007 to the PLC used) – Digital outputs of contact type

– M – Auxiliary relays (e.g. M000 -…) – Relay type bitable devices used to temporarily store some states

– S – Status relays – Used in STL to indicate a step (state) in the state of the machine

– T – Timer – Timer timers; are 3 ways: with increment of 100ms, 10ms or 1ms; Timers are 16 bits; can be retained (keeps the value until it resets) or without retention; the timer output is a contact that closes when the prefixed timer value is reached; the prefixed value is specified by a constant (preceded by the letter “K”, the maximum value 32767) or a data register (preceded by the letter “D”)

– C – counters – Are similar to timers, just as the increment is not controlled by time but by signal pulses

– D-data registers – Are 16-bit registers that are used to store process parameters or data; can address at bit level; for example, addressing bit 3 in register 0 is as follows: D0.3

– K, H, E – Numerical constants in decimal, hexadecimal or exponential form

PLCs read the signals from different sensors and input devices. These input devices can be keyboards, switches or sensors. Entries can be either digital or analog.

Check this out: http://www.plcacademy.com/plc-hardware-components/

Various types of proximity digital sensors can be used to control PLC inputs. Depending on the physical principle used, we distinguish several types of proximity sensors:

- Capacitive:- Determines the presence of an object in the perimeter of the sensor by the variation of the static around the sensor; Different types of objects are detected, regardless of the material (plastic, metal, glass, etc.); the detection distance is dependent on the size of the object, being in the range 0-2 cm.

- Inductive:- Determines the presence of a metal object in the immediate vicinity of the sensor by the magnetic field variation created by the sensor; the detection distance is much smaller (0-0.3 cm) and only ferromagnetic objects are detected.

- Optical:- Detects the passage of an object in front of the optical sensor by opting for the light source (e.g. LED)

- Mechanics:- Detects an object that by touching the sensor closes a contact (microswitches, limitations, etc.)